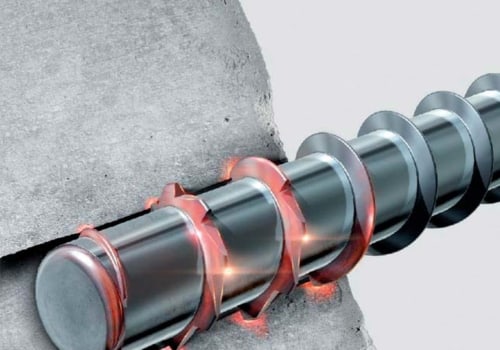

Concrete pumps are a revolutionary alternative to traditional methods of concrete supply, offering many benefits in terms of time and labor savings. But how do they work? The answer is really quite simple. Concrete pumps use a valve system and the basic principles of hydraulics to move liquid concrete from a hopper to the desired location. The operation of the concrete pump involves the use of two parallel cylinders, known as material and discharge cylinders.

The material cylinder pulls the concrete out of the hopper, while the discharge cylinder pushes it out of the pump. This process is repeated in tandem, alternately pulling and ejecting their volumes of liquid concrete. Most concrete pumps are connected to a truck or semi-trailer, while some are equipped with a remote-controlled articulated robotic arm (known as a boom) for precise placement. Boom pumps are used in most larger construction projects due to their high volume capabilities and labor-saving nature.

In typical concrete pouring, the goal is to place concrete as close as possible to its final destination in order to save transportation time and increase productivity. However, in many cases, the ready-mix truck cannot access the workplace. When placing a stamped concrete patio in a fenced backyard, a decorative floor inside an enclosed building, or working in a high-rise building, you must find another way to move concrete from the truck to the placement point. This is where concrete pumps come in handy. The concrete pump is designed to safely pump wet concrete through a pipe and hose supply system within its published classifications and specifications.

The simple answer to how concrete pumps work is that a concrete truck dumps its concrete into a hopper in the back of the pump truck. This type of pump is mounted on a trailer and concrete is delivered to the relevant area via a separate pipe that connects to the trailer. This pump requires steel or flexible concrete placement hoses that are manually connected to the machine outlet. To optimize the concrete pumping operation, the most efficient system configuration should be determined. Separate concrete placement booms can be used when a boom truck is not available or in situations where a boom truck cannot comfortably access the pour site. As long as the hopper remains full and there are no obstructions in the concrete hoses, the concrete pumping process goes smoothly.

The advantages of using a pump truck to place your concrete include; reaching homes and backyards, pumping up to multiple floors, placing concrete right where you need it, pumping quickly which saves labor costs, and reducing labor needed for laying down concrete. Concrete pumps are common accessories on construction sites today because they increase efficiency and productivity on projects such as high-rise buildings. They can be used for pouring foundations in housing developments or back gardens of houses.